OLD INFORMATION – I no longer run a straight blowback 9mm M16 unless it is for just testing / comparison purposes. I had broken several hammer pins and slightly egged out the hammer pin holes on a transferrable lower….some 15+ years ago.

Information is for references purposes….I would not recommend running a straight blowback 9mm upper on a transferrable lower today.

My Colt 9mm setup. I shoot mainly unsuppressed so I chose to go with this setup rather than get an integral suppressed upper. I contacted Gemtech to make me a barrel. The barrel I’m using is basically the same 5″ barrel used in the Gemtech Talon. I was going to get the exact barrel and Dr. Dater forgot to have them make me an extra one on their run of Talons so he made one on a lathe for me personally. Thanks Dr. Dater if you are reading this. I have now received my barrel back from Gemtech and now have it three lugged so I can move the can back and forth between guns easily and not have to worry about it unscrewing on me.

- Upper: RRA 9mm upper

- Lower: Full Auto Registered Receiver Colt SP1 that was converted to small pin by John Norrell.

- Handguard/Rail System: Pistol length FIRSH from Olympic Arms

- Scope Mount: BMAS Rail Extension

- Misc: RRA stock, KAC collapsible stock push button sling mount, CQB Solutions standard 1-1/4 3 point sling. KNS non-rotating trigger/hammer pins and a KNS front pivot sling pin since the barrel is so short. This works out well since I don’t have front push pin capability with the SP1 anyway.

- Optics: Docter Optics with factory Weaver mount

- Magblock: Tacbloc

- Suppressor: Gemtech MK9K

The picture above shows a modified curved Madsen mag. I was told that these were done for the Crossfire mag block which is no longer available. My Tacbloc is supposed to be a clone fo the Crossfire but I had to do a lot of grinding just to get it to fit in the magblock. Then sandblasted and parked. The mags definitely load easier than the Colts but of course they do not hold the bolt open after the last round.

Same configuration showing factory Colt mag

Same configuration but note this is before I had the barrel 3 lugged. Drum is by Mike Maguire.

This picture shows how the 3 lug is recessed in the handguard.

My 9mm Colt SMG bolt modified by SAW. I was very impressed by the fast turnaround and excellent workmanship.

They ramped the bolt and replaced the steel weight with one made from Tungsten. I’ve seen an ALL FACTORY COLT 9MM setup UNMODIFIED that stopped functioning. The hammer was hitting the back of the disconnector so bad that the tail end of it had snapped off so it wouln’t function in full auto anymore.

Another shooter I know was using an unmodified Colt bolt and broke his hammer/trigger pin unknowingly which egged out the hole.

I highly recommend that you get your bolt ramped if you run a Colt system 9mm upper. If you are not concerned about slowing it down as much as possible then don’t bother with the Tungsten weight.

My thoughts on the modified 9mm Colt SMG bolt by SAW

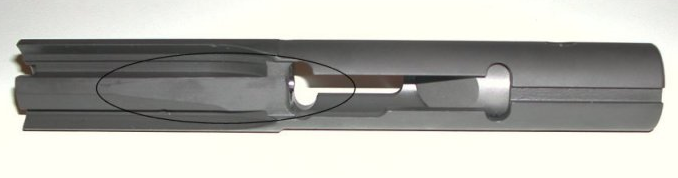

Before I got my bolt back from SAW, I went to a subgun competition with a friend and he brought his Colt 9mm SMG and he tried using someone’s SAW modified bolt and it would work in SEMI but not FULL. When I got my bolt back from SAW, I had the same problem. I figured out what the problem was. When they mill the ramp, they take off so much metal that the little bit of wear on the top of my hammer in my SP1 was just enough so that it would not push the hammer far enough for the auto sear to catch it. The lower is all COLT. I also tried the bolt in my ALL factory Colt 614 MG and it was having the same problem but not as bad. It was happening every time with the SP1 and about 20% of the time with the 614. It just so happens the hammer in my SP1 was more worn than the one in my 614.

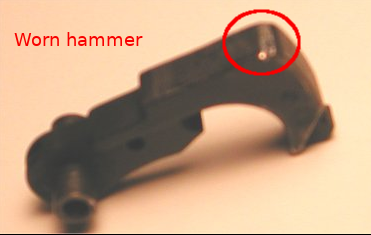

I put a brand new Bushmaster hammer in my SP1 and it works perfect now. It still concerns me that that the modified SAW bolt is so critical on the hammer. All my other uppers/calibers (223, 7.62×39, 22LR and of course the unmodified Colt bolt) don’t have a problem with the hammer that was worn. Below is a picture of the “worn” hammer. I don’t think it is that bad.

Update: I have since put the original Colt hammer back in and just grinded a little off the back of the hammer where it engages the auto sear so it would catch it earlier since the tip of the hammer is worn. It now runs 100% with the old Colt hammer.

I feel much better running the 9mm knowing that I am not damaging my lower with the rough shooting stock Colt bolt.

I did some testing of the Rate Of Fire with the three different buffers:

Ammo used was 124 GR JRN, Dynamit Nobel (Geco)

A PACT timer was used to get the RPM.

Used the same standard power collapsible stock spring w/ all buffers.

DPMS 2 Piece Mechanical – 615 RPM

AAC – 576 RPM

Colt Hydraulic – 703 RPM

Since the AAC was the slowest, I took the standard spring out and put the wimpy spring that comes with the AAC in the stock which I find works fine in stripping off the first round off a full mag fine for 9mm. This resulted in:

AAC w/ AAC weak spring – 521 RPM

AAC w/ AAC weak spring and with Gemtech MK-9K mounted – 630 RPM

I reload so I tried my normal load of 4.0 Grains of W231 behind a 124 GR JRN bullet and got the following:

Also note that this load is SUBSONIC in this barrel (at least it is in these Florida temperatures).

AAC w/ AAC weak spring / my reloads – 488 RPM

AAC w/ AAC weak spring / my reloads / MK-9K mounted – 549 RPM

I find using the weak spring too slow so I’m leaving the AAC w/ the standard spring in the gun. My main goal was to be able to get singles off in full auto which can easily be done with the AAC and stock spring

This is a modified Suomi drum mag made by Mike Maguire. He used factory Colt 20 round mags and welded them to the Suomi drum.

He uses plastic/delrin? for the dummy rounds rather than metallic ones like C&S and Vector does.

Same configuration showing factory Colt magame configuration