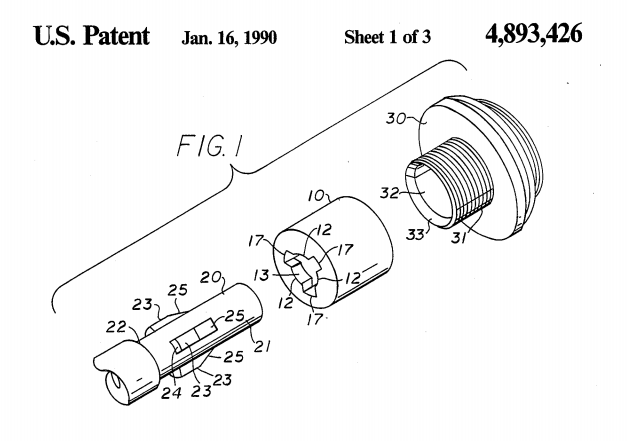

Tim Bixler (SCRC) was the first to come out with a successful 3 lug suppressor mount.

This was a brilliantly simple design which locks up rock solid and doesn’t use any springs that are susceptible to wear or heat. I have not seen or heard of any issues of these loosening up even under heavy full auto fire.

You don’t need any tools to tighten the nut either. Hand tight is fine.

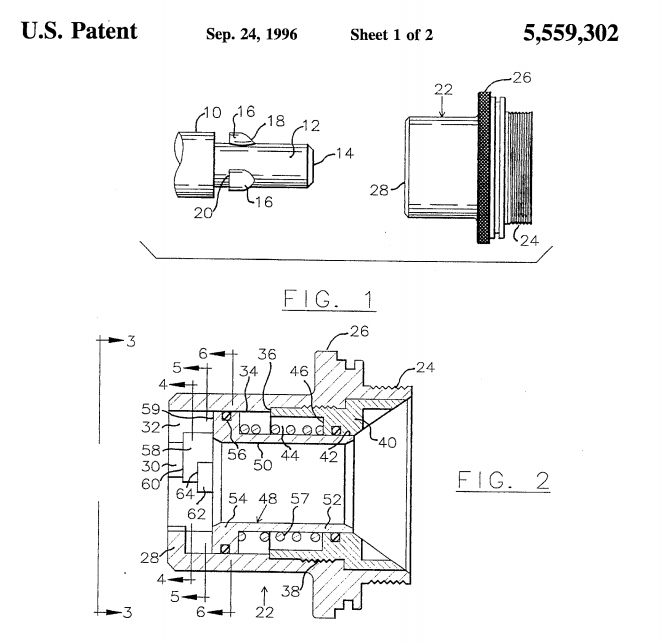

Gemtech used to license this design for several years until Greg Latka (previously of Gemtech) came out with a novel 3 lug suppressor mount design of his own.

This design is a little more complex in that it uses a cylinder which compresses a spring. This is what you more commonly see used on 3 lug suppressors these days.

Due to age, both patents are expired. Most manufactures seemed to have gravitated more to the Latka design.

Pro’s to the Bixler mount:

- No slop with the Bixler mount: There may be a slight rotational movement but no up/down or side-to-side slop that you can sometimes encounter on various implementations of the Latka design. I don’t think this is a slight against the Latka design. More an issue with variances in 3 lug mounts out there. However, the Bixler design seems more tolerant of these variances since you can just tighten the collar and remove any slop….EX: I have some combo’s where a Latka mount may have a considerable amount of slop but if I put a Bixler 3 lug mount on the same 3 lugged barrel, it is rock solid.

- Nothing to wear out on the Bixler design: no springs or o-rings to wear out on this design.

- Nothing to get seized up from fouling which can happen on the Latka mounts – again, this may just be due to manufacturing tolerances

- Possibly stronger as the original Bixler design had a steel nut (though Gemtech made them from aluminum) – I have run steel Bixler mounts on full auto .308’s with no issues

- It is the original taper mount that seems to be all the rage these days. As mentioned in the patent, “the front end 25 of each lug is tapered inwardly to correspond to the angle of the chamfer 33 of the threaded member 30″

Con’s to the Bixler mount:

- Slower to mount/dis-mount

- Requires you to access the rear nut IF the mount unscrews from the can body if tucked deep inside a rail.

Some various cans using the Latka mount.

Notice the two MK9K’s at the top are using two different Latka 3 lug mounts. The one on top being older than the skinnier ones they were starting to use during that time period. It was easier to make one mount for all their cans but myself and others were having POI and fouling issues with the skinnier mount. They later went back to the fatter mount.

The older mount disassembled from the inside but was sealed against fouling while the later design leaked gas into the mechanism.

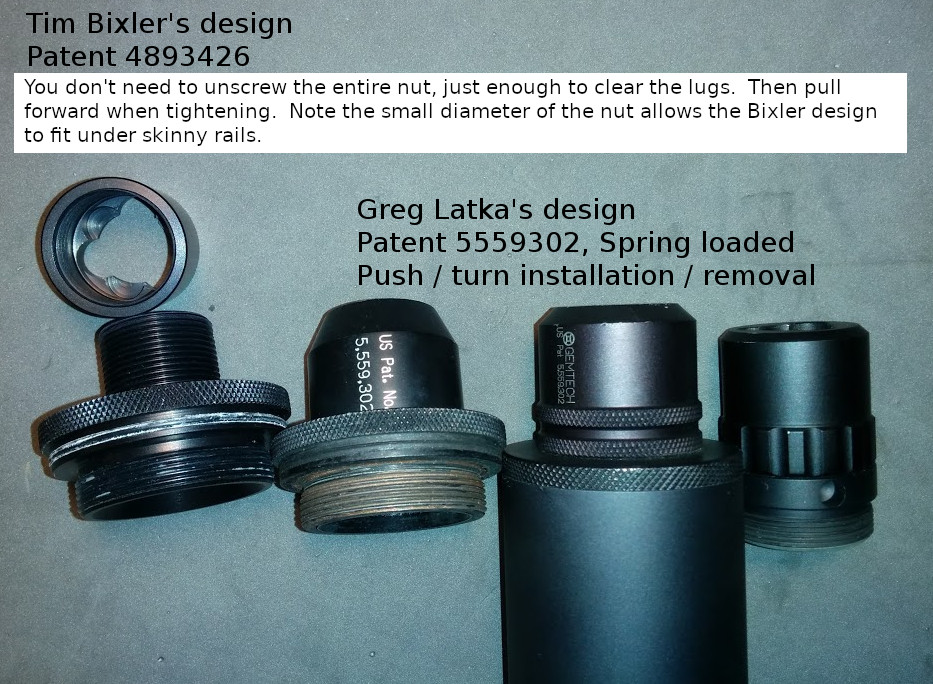

Picture below summarizes some of these variants.

When I had Joe at Curtis Tactical make my custom hybrid MK-9K suppressor, I told him that I wanted him to use the old SCRC 3 lug design. He had never heard of it so I sent him a bunch of pictures and ultimately let him borrow one of the 3 lug nuts for cloning.

Pictured below is an old Bixler design MK9K mount and nut made from aluminum and licensed from SCRC. Original steel SCRC nut on the right.

This view compares the aluminum Gemtech 3 lug nut to the more intricately machined steel SCRC nut. While I admire the machine work, I don’t think it is required for proper operation / performance. So Curtis Tactical cloned the Gemtech style of doing round holes.

This view shows how the inside of the mount is tapered to reduce weight.

The typical push / turn 3 lug mount OD is too large to fit inside the proprietary handguard of the CMMG Dissent.

Joe previously of Curtis Tactical is now at Shaw Armament and is offering the Bixler mount in various thread patterns: https://www.shawarms.com/products/thundercan-41182-11646-5176

Hansohn Brothers also posted recently they are going to start having them made and selling them 4th quarter 2024.

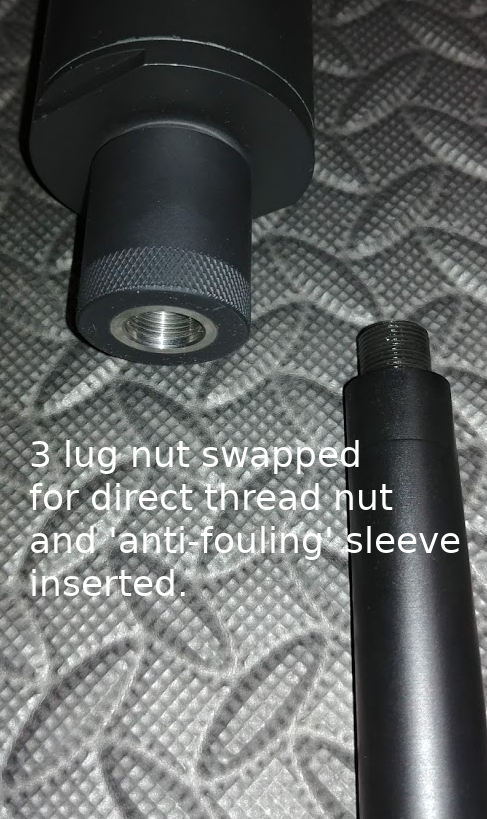

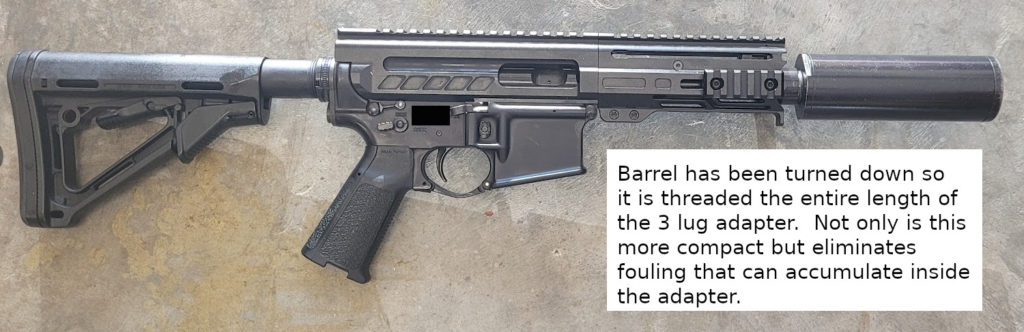

This is an innovative idea for a direct thread option using the Bixler design from Joe at Curtis Tactical.

He made a Titanium nut that is threaded for a direct thread barrel so you can leave the rear mount intact. He also added an ‘anti-fouling sleeve’ to go inside the rear mount so there would be no carbon buildup when using a direct thread barrel. Great attention to detail!!