This is provided as informational only pertaining to LEGAL conversions of the UZI family from semi to full auto.

Note that most of this information is mirrored on UZITalk.com

A very common question regarding UZI conversions is, “Who did the best conversion?”. That is a hard question to answer as these guns were converted before 1986 and who knows what was done to the gun after it left the original manufacturer’s hands. I use the term manufacturer because some UZI’s weren’t converted by a C2 but by individuals on a Form1. Billistics stands out as one company that did the most complete factory correct conversions. Buyer beware though, when Billistics went out of business there were a number of guns including UZI’s that were registered by them but were converted by others. I personally almost bought such an UZI because the seller boasted it was a Billistics gun but upon inspection it only had the rail removed and NOTHING else was brought to SMG specification. So the best thing is to know what to look for. Hopefully, the information here will advise you on what to look for and you can decide what is important to you.

The 3 different UZI “versions”

The full size UZI which came as the Model A and Model B

The MINI UZI Carbine – which all evidence shows that they did not enter the US until 1987. Note that the SMG version was in the US before 1986 which would all be Pre86 Dealer Samples and NOT transferrable to an individual.

The UZI Pistol which came into the US in 1984.

Here are some details that all the SEMI’s share but there are exceptions:

The receivers are marked as SEMI’s.

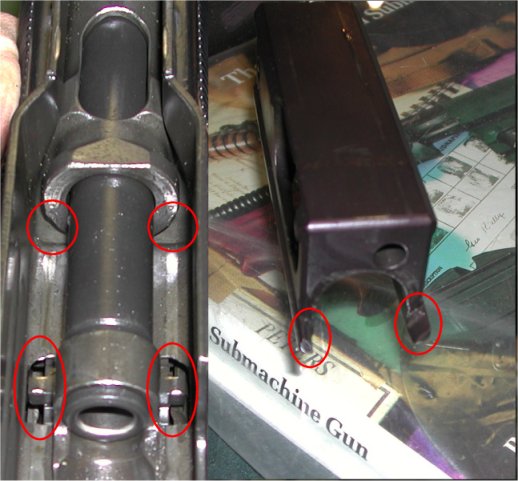

They are all closed bolt. Note that for FA use, the bolts must have the lower “lip” as seen in the picture below. This is true for both OPEN and CLOSED bolt FA operation.

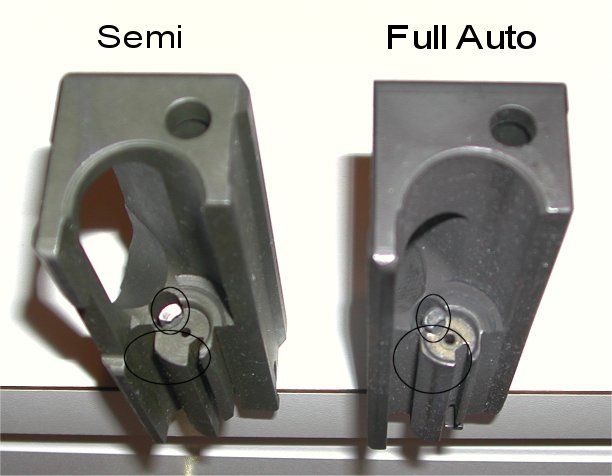

The SEMI extractors are different from the SMG extractors. Below you see a SEMI extractor in a semi bolt on the left and a full auto extractor and bolt on the right.

They all use SEMI sears which are smaller. Because of this thay also have a smaller opening in the bottom of the receiver so that the larger SMG sear will not fit. Below is a picture of a NON converted SEMI Model A’s sear and openings in the bottom of the receiver. The openings may look large enough to accomodate an SMG sear but they are not.

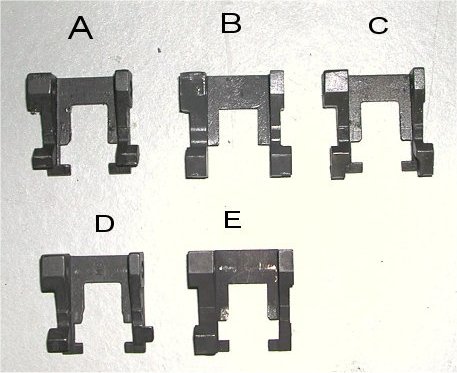

Below are some different sears:

A – Semi sear

B – SMG open bolt sear

C – SMG open bolt sear that has been relieved on the sides to accomodate the barrel restrictor ring.

D – MINI Carbine Semi sear

E – SMG Open bolt sear that has had the right side chopped off for use in a Closed bolt setup for a MINI or MICRO. This one’s right “ear” broke off which is what the grip safety needs to work. This one should not be used.

They all have non-ratcheting topcovers with the legal disclaimer on the top of the slot cover.

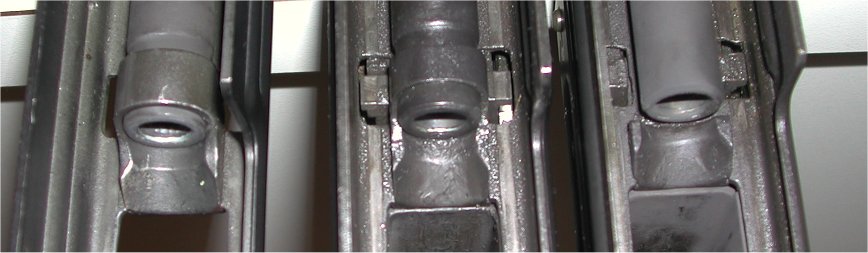

Below you can see how one topcover has the ratcheting teeth and the other does not. These are MINI topcovers. I made a big circle showing that the topcovers cocking lugs slot go back the same distance for charging the bolt. This is NOT the case with a SEMI FULL Size UZI topcover. To use a Semi Full Size UZI topcover for FA Open bolt operation, that slot would have to be made longer.

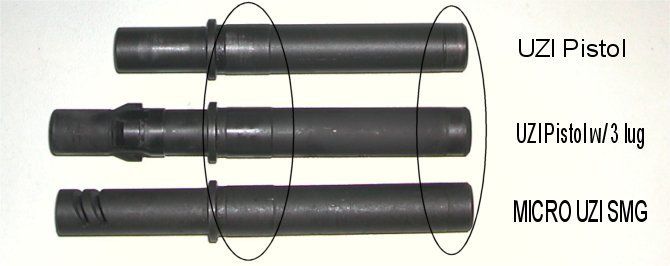

They have barrel restrictor rings which restrict the installation of a factory SMG barrel or SMG bolt — EXCEPTION — the factory SMG barrel for the MICRO is relieved for the ring as the factory MICRO SMG has the ring too.

Below are 3 different approaches to dealing with the ring.

1. The one on the left shows an unaltered barrel restrictor ring. In regards to the full size UZI, leaving it alone requires that you must use modified SMG bolts (or a Group bolt as mentioned below) for the SMG Open bolt and modified/cutdown barrels. Note that with the Closed Bolt MINI/MICRO, the ring does NOT obstruct the FACTORY IMI SMG Closed bolt but like the full size it does obstruct the OPEN bolt.

2. The one in the middle shows a ring that has been trimmed down. This provides the advantage of interchangeabilty of SMG bolts and better supporting of the barrel than no ring but limits the owner to using modified/cut down barrels.

3. The one on the right is an example of the ring being milled off completely. This allows for interchangeability of all factory SMG parts and leaving the SEMI feed ramp in allows for excellent feeding of virtually all ammo types.

Mentioning the ring brings about the topic of bolts that work with the ring. Group Industries machined their semi and SMG bolts so that either one would clear the ring for ease of manufacturing rather than doing two different ones. Using a Group bolt, the manufacturer wouldn’t have to worry about messing with the ring or modifying a bolt. Fleming commonly did this.

Below are some pictures of an IMI and Group .45 bolt. Note how the Group bolt is machined to clear the ring. This is the same case with the MINI Group bolts.

You can see in the picture below that Group engraved a “G” on their bolts near the extractor retaining pin.

They all use a 9mm diameter trigger group lug that is welded on the bottom of the receiver. This is to prevent installing an SMG lower on a SEMI receiver. — EXCEPTION — the factory MICRO SMG and UZI Pistol both use a 9mm trigger group lug/pin.

Picture below shows a bushing that has been installed so that a SMG pin/lower can be properly installed. Rewelding this area rather than using a bushing is also an option.

The lowers all have a block welded to the bottom to prevent the selector from moving to the full auto position. The lower on the right was from a Fleming conversion where the block was milled off.

The lowers were marked just “F” and “S” for Fire and Safe. Below is a picture of a lower that had the “A” added as well as the additional notch. Fleming either left it like as seen below or he also changed the “F” to look like an “R”.

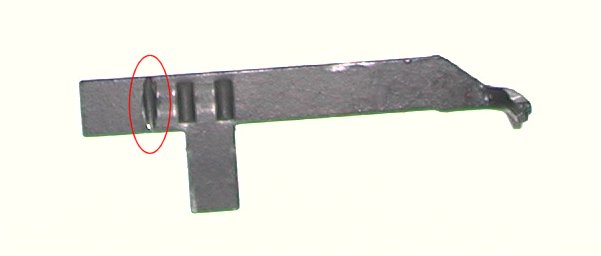

The selector bars are notched for safe and semi only. Below is a selector bar that has had the additional full auto notch ground in.

They have trunions that are different from an SMG trunion.

Full Size: The trunion is a smaller diameter on the threaded end to prevent insertion of a factory SMG barrel

MINI Carbine: The inner dimensions do not restrict installation of a SMG barrel. It is the restrictor ring that stops that. The trunion is different to an SMG in that the bottom of it is not relieved to accept the “feet” of a factory SMG OPEN bolt.

Pistol: — EXCEPTION — Trunion is the same as on a factory MICRO.

The stocks are identical to the SMG models with the exception of the UZI Pistol having no stock. Another exception would be the POST BAN UZI’s which have fixed stocks.

With the exception of the UZI Pistol, they all have bayonet lugs. Note that later versions of the MICRO UZI’s have this bayonet lug which is more like an “accessories” lug. Again the POST BAN UZI’s would be an exception as they have had their lugs removed.

They have provisions for mounting a sling with the exception being the UZI Pistol. The factory MICRO has a sling pin in the left front sight “ear”.

So what are the various conversion methods?

Below is a general summary of the various methods. Each method has its on implications pertaining to each UZI model. Those implications are detailed further on the webpages for each respective model.

Registered Receiver – Usually the most desireable, due to being the most versatile and capable of being “factory” correct.

An exception to this would be that there are some registered receiver full size UZI’s that do not have the bolt blocking rail removed. This would be the least desireable because ATF would frown upon removing the rail at this time. A gun like that should have had the bolt registered not the receiver.

Registered Bolt – These are usually slotted OPEN bolts. They are normally a regular SMG OPEN bolt that has been slotted to clear the bolt blocking rail and have been milled to clear the barrel restrictor ring of a semi auto full size UZI receiver.

There are unusual permutations of these including ones that were registered closed bolts. Fleming did do some MINI Closed bolt conversions.

There are quite a few registered bolts that were cut down for use in a MINI or MICRO/UZI Pistol. Remember that the MINI and MICRO/UZI Pistol never had the bolt blocking rail. Note that you could move the bolt around to the other UZI models with the bolt provided you fabricate special cocking lugs for the respective topcover.

Registered Sear – Most of these are Fleming Registered sears that are permanently married to the receiver. Qualified also did some registered sears that are NOT married to any receiver but these are extremely rare.

Registered LaFrance MG Conversion Kit – These consisted of a short barrel, slotted bolt and modified lower. These had all of his information engraved on the front of the magwell and such are sometimes referred to as a registered “lower”. There was also a matching serial number on top of the bolt and usually his logo above it.

“Possible” registered “kicker” – These were mentioned in an old Sept 1984 issue of “Firepower” magazine. Being that they were around at that time, there is a possibility that there could be some registered.

FULL SIZE UZI

The ATF opinion appears to be that you can do just about anything you want to the receiver to bring it up to SMG spec. What they do have a problem with is removing the bolt blocking rail. Here are the direct links to the ATF opinion letters that pertain to this:

ATF Letter 46

ATF Letter 61

Registered Receivers and the Bolt Blocking Rail

All SEMI auto Full Size Uzi’s had a bolt blocking rail welded in the receiver as seen below. This prevented the use of inserting a factory open SMG bolt which is not slotted.

Most will agree that a Registered Receiver conversion that has had the bolt blocking rail removed is the best to have for a full size UZI conversion.

Below is a picture of what the bolt blocking rail looks like in a Semi Auto Model A UZI.

There are some registered receiver full size UZI’s that do not have the bolt blocking rail removed. These guns were converted via a slotted bolt that has no markings. This would be the least desireable because ATF would frown upon removing the rail at this time. A gun like that should have had the bolt registered not the receiver.

ATF does not approve of this because they think that is “freeing up another MG” because a slotted UZI bolt is considered a MG which would no longer be used if the rail was removed and a factory bolt used instead.

Barrel Restrictor Ring

Already discussed above.

Bolts

Quite a few people did registered Bolts but the most common is probably a B&G registered bolt. This is just a factory SMG bolt with a slot milled in the side of it to clear the bolt blocking rail. Below is a picture of a registered B&G bolt.

Also note that there are some registered bolts that are closed bolts but those are very rare and not very desireable since it is a welded on lower lip.

It has been reported that some VERY early Model A’s came into the US that had the lower lip on the bolts. This would allow FA functioning by just modifying the lower. ATF had stopped their importation and only a few of them exist.

Sears

Sears were discussed on the main conversion page. In regards to the registered sears, Fleming removed the bolt blocking rail from the receiver and engraved his information on the bottom of the receiver as seen in the picture below. The sear was also crudely engraved with the same info with a vibrating pencil engraver. These sears are permanently married to the receiver and cannot be removed. While this information may not be documented on the current form that the gun is on, it should be.

Qualified did some registered sears that are not married to the receiver but are extremely rare.

Trunion

The trunion is a smaller diameter on the threaded end to prevent insertion of a factory SMG barrel

Barrels

A. Factory IMI Chrome lined SMG barrel. Note that the SMG barrel has the larger diameter band after the flange.

B. SMG barrel that has been turned down to fit in a semi trunion and barrel restrictor ring.

C. Chrome lined Bushmaster barrel. Note that this barrel has the secondary band for maximum support. If this barrel was installed in an unmodified semi receiver it would be supported by the ring, rear and front of the trunion.

D. The Bottom barrel is chrome lined and possibly an IMI cutdown. Note no secondary band so support would be by the front of the trunion and barrel restrictor ring.

Remarking the Receiver

Most conversions were not remarked. Fleming did a “Basic” and “Deluxe” UZI conversion. The Deluxe consisted of remarking the receiver to say “UZI SMG”. A factory IMI UZI should really be marked “SMG UZI”. The Deluxe also had the lower remarked to ARS while the Basic usually was AFS.

Back in the 80′s, UZI parts were harder to come by and more expensive. Today, UZI parts are much cheaper and easier to come by.

Mini UZI

The MINI Carbine did not enter the US until 1987 so the options are more limited. The MINI UZI SMG was in the US before ’86 as Dealer Samples so there were some around for C2′s to copy from to make RR’s out of them from chopped down and re-welded full size UZI’s like Vector has done after ’86. In particular, Fleming did some of these.

Sears

The Fleming Registered sear MINI are permanently married to the receiver. Fleming was registering regular UZI SMG sears before ’86 then after ’86 removing the bolt blocking rail out of the full size UZI and relieving the trunion on the MINI UZI to accomodate the “feet” of the factory OPEN bolt. ATF stopped him from doing anymore in 1988. So there is a window of 1987 – 1988 when these MINI’s were done. This is the only option to have a fully transferrable MINI that has the relieved trunion and is NOT a re-weld.

While there is nothing wrong with most re-welds, this is the closest to possibly get to a factory MINI SMG that is fully transferrable.

Qualified also made some registered sears that were NOT married to any receivers but they are extremely rare.

Bolts

Before the Vector MINI’s, the most common of the MINI conversions was the bolt gun. These were made from registered full size UZI bolts. Most of the registered bolts were not cut for the feet as most people didn’t realize that you could make the feet smaller to fit under the trunion without modifying it.

Note the feet of the bolt

So what happens when you don’t have the “feet”?

For comparison, this is a picture of a full size UZI with its bolt charged. Notice how much distance there is between the bolt face and the back of the dummy round.

Now here is a MINI UZI with the proper bolt with feet.

UZI’s that don’t have the feet still run fine but there is one problem. To avoid malfunctioning on the first round, the bolt should be forward when inserting a loaded magazine otherwise the bottom of the bolt pushes on the back of the round causing it to tilt up.

This particular photo shows a bolt with no feet in a MINI UZI utilizing a proper SMG sear.

This picture shows a MICRO UZI with a bolt w/ NO feet and a SEMI sear. Note how much the ejector is seen in the picture versus the other pictures.

All the pictures above shows what happens when inserting the mag in a bolt that is charged. This photo shows a round being pushed forward slightly. In this case, the UZI will not jam as the bolt was forward then charged AFTER the mag was inserted. (In this case, it is a MINI UZI w/ a SMG sear. SEMI sear works fine too.)

Trunion / Barrels

Unlike the full size UZI, the inner dimensions of the trunion do not restrict installation of a SMG barrel. It is the barrel restrictor ring that stops that. The trunion is different to a SMG in that the bottom of it is not relieved to accept the “feet” of a factory SMG OPEN bolt. Another difference is that the MINI’s trunion is “skeletonized”.

Below are three MINI barrels. The top barrel is a factory MINI Carbine barrel. Note that there is no secondary barrel band so the barrel is supported by the band behind the flange and the tapered end for the barrel restrictor ring.

The middle barrel is a factory IMI MINI SMG barrel that has had the breech end turned down to go in the barrel restrictor ring. Again, unlike the full size UZI, this is the only modification needed to fit in an unmodified MINI CARBINE receiver.

The bottom barrel is an unmodified factory IMI MINI SMG barrel.

More details of the trunion will be depicted below when discussing the Vector MINI conversion.

Vector MINI (Registered Receiver)

Fortunately for many of us, Vector has come to the rescue by making more MINI’s available to the transferrable market. These were done by taking some of their transferrable Group Industries receivers and modifying them to MINI spec.

Here are some of the details:

The full size IMI or Group receivers were not designed to accept the “feet” of the MINI OPEN bolt.

On some Vector MINI’s holes were left in the receiver for the feet to poke through. This example shows where they did weld over the holes. The vertical circle shows the area that was cut and rewelded.

This is an early Vector MINI where they were trying to copy the rear ribs of an IMI MINI. They had to stop short to not mess with the original manufacturer’s markings. A real IMI only has 1 long rib on the left side rather than two.

Again, this long vertical circle shows approximately where this receiver was re-welded.

This is a Fleming MINI showing the left IMI rear “rib”. Fleming had them engraved this way rather than the factory which is just “MINI UZI”.

Right side of the Vector MINI with two small “ribs”. Also note the use of the Model A style sights. Very early IMI prototype MINI’s had these but most evidence shows that the production MINI’s had the Model B style sights. Vector does offer the Model B style as an upgrade.

IMI MINI’s two right rear “ribs”. Also note the Model B style sights found on basically all production MINI’s.

Here you can see that the “ribs” are indentations like the other ribs. Hard to see in this picture but in person you can see the welds going through the middle of some of the “ribs” on the inside.

Vector trunion. They use the same trunion from the full size UZI. Note the Model A style sights.

IMI MINI trunion. Notice how it is “skeletonized”. Also note the factory correct Model B style sites.

Vector trunion that has been relieved to accept the “feet” of the MINI Open bolt.

Here is a picture of an IMI MINI UZI conversion that a dealer had at the Spring 2004 Knob Creek. I don’t know if it was a registered sear, bolt or what. They weren’t too willing to find that out for me. Note that it has a semi sear so I doubt it was a registered sear but also note that the receiver was opened up to accept a SMG sear. The trunion has been unmodified. The bolt however appears to be a factory MINI bolt. It didn’t look like a full size that was rewelded. Note how the feet have been modified to work with the unmodified trunion.

Micro UZI

Many of the UZI Pistol conversions are registered UZI bolts like the MINI. Also like the MINI, the Pistol has no bolt blocking rail. Since the UZI Pistols were in the US around 1984 there were some that were registered receivers. Some of the manufacturers that did do some RR UZI Pistols: Wilson Arms, Fleming and Hard Times Armory. LaFrance did quite a few UZI Pistol conversions for the movie industry.

Sears

Fleming has stated that he did do some registered sear UZI Pistols but those appear to be very rare as they rarely show up for sale.

Bolts

The MICRO was never offered as a factory OPEN bolt Full Auto. They were all closed bolt. Most of the UZI Pistol conversions however are OPEN bolt. The Closed bolt is said to be unreliable in the MICRO but hey can be made to run. Note that the MINI and MICRO both use the same closed bolt assembly. The only difference being that the MICRO’s bolt has a notch in it to accomodate the topcover’s cocking lug.

For open bolt, the UZI Pistol has the same issue as the SEMI MINI UZI in that the trunion is not relieved to accept the feet of a MINI Open bolt. There have been several approaches to this.

1. Use a bolt with no feet and those issues are addressed on the MINI conversion page.

2. Use a MINI bolt with feet. Some UZI Pistols did have the trunion’s relieved for this.

3. Use a bolt with modified feet to go under the trunion. I have seen a RR UZI Pistol that had a modified MINI bolt in it that had VERY thin feet to go under the trunion.

Barrels

Unlike the Full Size and MINI, the Semi and Full size factory barrels are interchangeable. This was probably done since they are both short barrels.

Stock

Obviously, the UZI pistol does not have a stock. This is a stock buttplate made by Vector for their MINI UZI’s.

Sling Pin and Bayo/Access Lug

The factory MICRO has a sling mount on the left front sight “ear”.

This is a picture of a factory MICRO with the front sight sling pin installed and the bayonet/accessory lug circled.

From this picture you can again see the front sight sling pin. Note here that the factory MICRO front and rear sights are different from the UZI Pistol. The UZI Pistol sights are designed to be used at arms length while the factory MICRO is designed to be used with the side folding stock. This factory MICRO also uses a semi sear and the openings are NOT bigger for the larger SMG sear. Note that the barrel restrictor ring is in this factory SMG which is contradictory to the factory full size and MINI UZI SMG’s.