In my testing I have found that the best buffer, tube and spring combo for the CMMG RDB to be:

- A5 or equivalent buffer tube

- Kynshot 5007 hydraulic buffer – think of this of an A5 length hydraulic buffer not as a PCC buffer

- Tubb 556 or 300 BLK flat wire spring – the 300BLK spring will give about 30 RPM slower cyclic rate. If you don’t care about slowing down the cyclic rate I’d recommend sticking with the 556 spring as you can use all the above in just about every 556 configuration and I think you will find it to be superior to almost any other buffer / spring combination especially noticeable in full auto.

This also happens to be one of my favorite buffer/spring configurations for 5.56 as well (although I use the 556 Tubb spring no the 300BLK spring for 5.56)

Here are the results of the configuration above using all unmodified parts (in the picture below that is with the 556 Tubb spring). 622 RPM.

Same configuration suppressed (and 556 Tubb spring) 686 RPM:

Bear in mind that while many people have taken my advice and used this combination for their CMMG RDB builds (and now 556 and other builds), this is NOT recommended by CMMG. I believe that the CMMG RDB has more reliable ejection the faster the carrier is moving (within reason).

CMMG recommends their 9mm customers to run a standard carbine buffer, spring and tube. However, I think hands down anyone that has compared that configuration to this will tell you this is a lot smoother.

While the above buffer/tube/spring configuration is good, I was still comparing side by side a full auto MP5 trying to rival it’s smoothness. I think it was close unsuppressed but still not quite there. Suppressed, I felt that the MP5 was still considerably smoother.

I tried adding the optional weights to the carrier but found that increasing reciprocating mass just makes the gun too bouncy. The MP5 gets its smoothness not by adding weight but by controlling the delay. Same goes here.

Back when I was working on the prototype 9mm Piston AR upper with the other C2, we were using 5.45x39mm bolts since the bolt face is basically identical to the case head of a 9mm round. So I dug up some of those bolts and had them modified for the CMMG RDB. As pictured below left to right, CMMG 9mm bolt, 5.45 bolt w/ lugs cut to be less aggressive than the 9mm and modified tail, 5.45 bolt with just the tail modified, unmodified 5.56 bolt for comparison.

Going with a modified 5.45 bolt obtained the cyclic rate and smoothness I was looking for and not add any additional reciprocating mass.

In the video below I was trying do all shooting from a lead sled to reduce the human factor as much as possible. I don’t know why but in the factory config it would jam if fired from the lead sled but functioned fine from the shoulder. Anyways for these two rounds you can get the idea of the recoil impulse.

And now my recommended buffer/tube/spring combo with a modified 5.45×39 bolt. You can barely see movement when the shot if fired. In this video I was using the 556 spring instead of the 300BLK spring and that 5.45×39 bolt was tuned to run only with the suppressor mounted so I didn’t get last round bolt hold open.

Now adding a suppressor to this configuration and subsonic ammo, this runs 100% and as you can see very smooth.

Side by side comparison to MP5K PDW

After I had done all this tinkering CMMG then came out with their .40SW RDB and I was eager to check out the angles on that bolt.

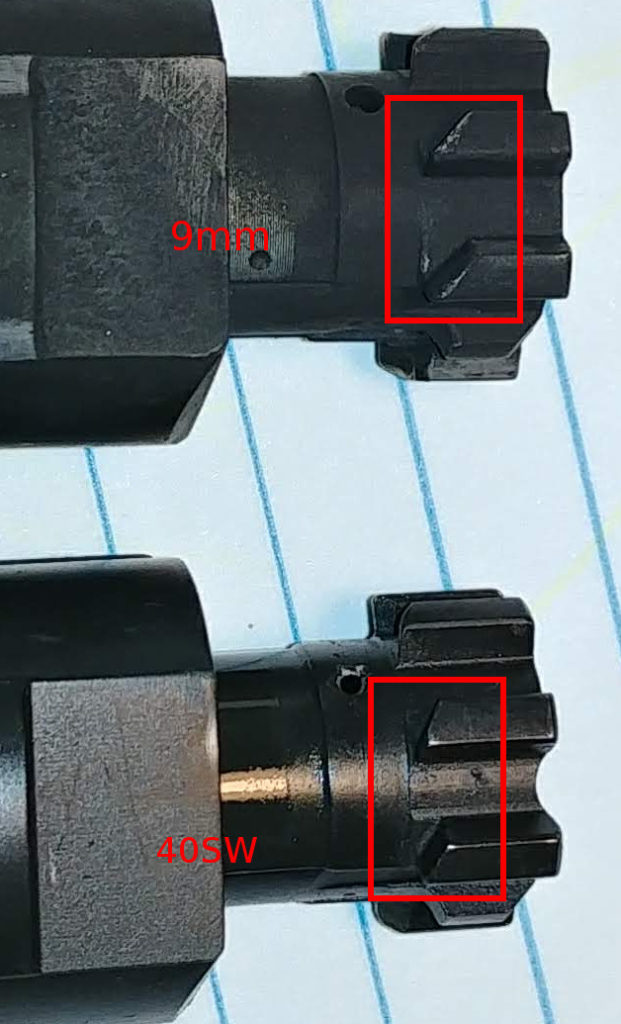

In the picture below you can see how the angles of the .40SW bolt are not as sharp as the 9mm bolt. .40SW is higher pressure and so the less aggressive angles delay the bolt more. I have UZI bolts that have been bored out for .40SW that still work fine in 9mm so was hoping I could do the same for the CMMG RDB.

What I’ve found is that the .40SW bolt only works with a suppressor mounted when used in 9mm. Just like what I was trying to do with the 5.45 bolts. I would also think using the .40SW bolts may be better since it has the factory heat treat.

Pictured below are the results of the using the .40SW bolt in 9mm, 300BLK Tubb spring, RB5007 Hydraulic buffer and A5 tube. Great cyclic rate and very soft/smooth.

However, messing with the bolt angles, you may have ejection issues as now the BCG is not moving as fast to reliably kick the brass out with the spring loaded ejector.

Ive’ done a lot of documentation and testing with the ejector spring failures and finally got frustrated with dealing with it. I contacted the C2 that I worked with on the prototype gas piston operated 9mm AR15/M16 upper. We had used a high speed camera to determine that a fixed ejector would be required to make it reliable. We both had our other products we were selling at the time and didn’t want to move forward with the project. I moved on but he later continued to work on it and he was able to supply me with a fixed ejector that works wonderfully for the CMMG RDB. It requires a modified upper, bolt and carrier. Unfortunately, he doesn’t want me sharing any pictures of the design.

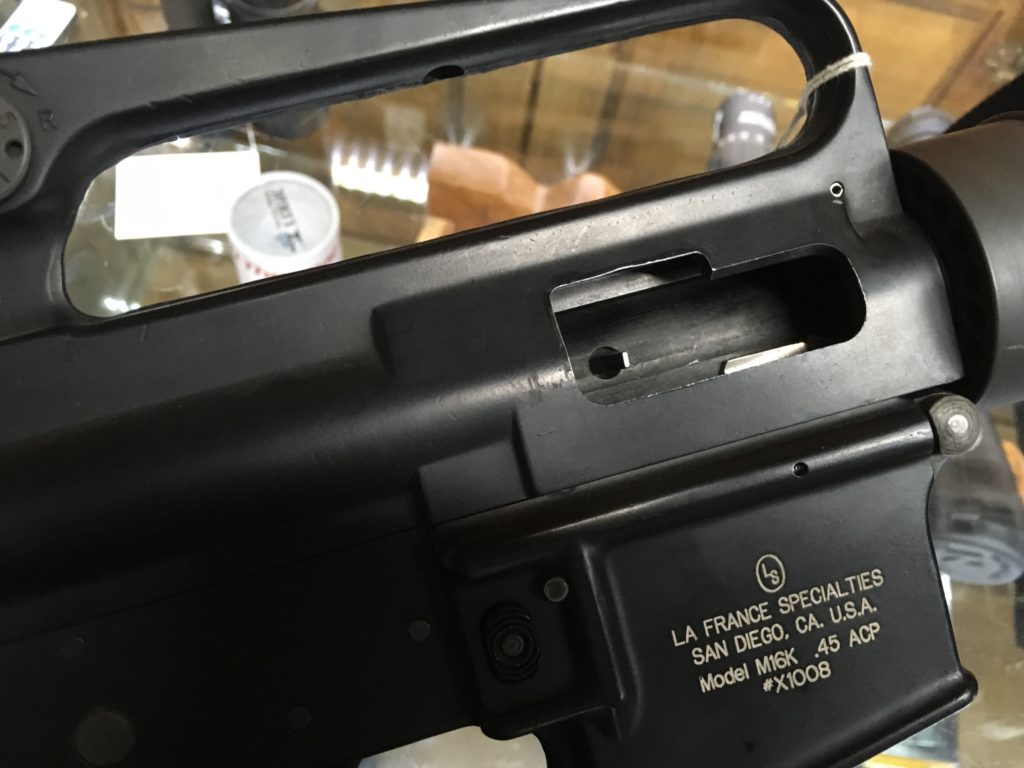

All that said, I found this old picture I saved of the fixed ejector of the LaFrance 45K which is straight blowback to give you guys some hints…Thanks goes out to whoever took this picture. I can’t remember where I got it.

What I will say is that this is how the CMMG RDB should have been brought to market. All of my reliability issues have gone away moving to the fixed ejector. On the ejector spring issues page I briefly mentioned about having a custom SS barrel made where I had all the headspacing slop removed. I had DeadShot barrels do this work for me. He was not familiar with the CMMG RDB design and so I shipped him a 9mm CMMG BBL / BCG as well as a SS blowback barrel and standard 556 extension to mate with the blowback barrel. He agreed that headspacing was excessive on the CMMG barrel.

I also shipped a .40SW CMMG bolt as I wanted him to headspace the 9mm barrel for the .40SW bolt not a 9mm bolt.

Below are some pics of the custom SS barrel. I used an old 5.56 LWRC NiBOR extension and a special 3 lug adapter that is threaded almost the entire length to reduce the freebore condition and have the rifling go almost to the end.

Since this barrel has all the headspacing slop removed I was curious to see if the spring loaded ejector would work with it but turns out it does not. By not having the slop that ‘shock’ doesn’t happen and the bolt is robbed of more energy and moving slower than a barrel with sloppy headspacing. This slower moving bolt results in ejection failures with the spring loaded ejector, however with my fixed ejector setup it runs perfectly fine.

Also, I’ve had several people ask me about the extension used on the CMMG RDB and while their patent does reference a proprietary extension where the back of the lugs has corresponding angles to interface with the bolt lugs, I don’t see that in any of the 3 factory CMMG barrels I have. They all look like a standard extension. See picture below that I took of one of my factory CMMG RDB barrels with a bore scope.

Re-did the cyclic rate test using the new custom barrel that has the headspacing slop removed. Yields a slightly lower cyclic rate suppressed. Also using the new Curtis Tactical CT9KS suppressor. This was using my 147GR reloads. 3.7G Titegroup. I have run this configuration the most and it has been very reliable.

Here is slow motion video of the configuration above running a 10 round mag dump.

I had the carrier key cut down and the carrier put in a lathe to allow increased travel matching the Surefire Suppressor Optimized Bolt carrier. That system comes with a proprietary buffer and spring designed to fit in a standard carbine length buffer tube. However, since I am using the A5 length tube, I can use a standard carbine length buffer with the addition of a thin spacer to prevent it from bottoming out. The hope was to reduce the amount of reciprocating mass. If you look at the high speed videos above, the recoil impulse has been greatly reduced but you can still see the gun shift forward when going into battery due to the amount of reciprocating mass.

This configuration has not been as reliable as using the RB5007 and standard length carrier key. So I have gone back to the configuration above.

Update 1/24/24

My friend gave me permission to share the details on the fixed ejector. I have posted in forums that this thread is very close to his setup: https://uzitalk.com/forums/index.php?threads/i-did-it-fixed-ejector-rdb.97420/

Here is a link to my friend’s patent: https://patents.google.com/patent/US10690425B2/en?oq=10690425

Below is a picture from the patent showing the fixed ejector. Note that his system is piston operated and the action is truly locked NOT delayed. There is no issue of a bolt failure with his system. He may be doing a production run soon but as of right now his system is not for sale.

Many have asked me to share details of the fixed ejector with the CMMG but as I have mentioned on several threads, the bolt finally broke on mine (I estimate at least 25K rounds).