TLDR Version:

- The slop between the bolt lugs and the extension lugs kills the ejector springs. Scroll down to look at the videos for clarification. The ejector spring in a 556 is not an issue since that bolt is truly locked. Not so with a delayed blowback setup. I am not a fan of any ejector spring that is inline with the recoil impulse of a delayed action. I had the same failures with the MEAN Arms bearing delay. It actually lasted less rounds than the CMMG RDB ‘Guard/Banshee’.

- If you remove the slop by getting a custom barrel made, the impulse will be so soft that the case won’t eject and then a custom fixed ejector is required but then that will weaken the bolt which will eventually crack (mine did at around 25K rounds).

- I have never personally seen a CMMG RDB ‘Guard/Banshee’ run hard (full auto, suppressed) for over 1500 rounds without the ejector spring failing. I had (2) 9mm CMMG RDB ‘Guard/Banshee’ setups and they both had the issues. I have several friends that all suffered the same fate. I see online some people saying they have more than 1500 rounds with no issues. If this is true, my only guess is their bolt / extension slop happens to be ‘perfect’, I just have never seen it myself.

- Some people report of immediate failures not even making it through the first 50 round box of ammo. In those cases, I would say to make sure you are running the CMMG recommended baseline configuration: milspec spring, standard carbine spring, standard carbine length buffer tube, their upper or a .458 / XL enlarged upper and quality factory ammo. I know many have posted great success with using a standard 556 upper which is fine if you don’t have problems. I’m saying all this to minimize the variables and get factory support. They will probably tell you to go to a heavier buffer, send you a tuning kit and maybe a replacement bolt depending on age.

- Are you running suppressed? See my video below where I had an early barrel which had excessive slop between the bolt and extension lugs which was resulting in broken cam pins, broken firing pins, breaking the extractors and killing the FP springs quickly. I noticed that if I removed the extractor from the bolt, that barrel would extract rounds with NO suppressor mounted while the ‘good’ CMMG 9mm and .40SW barrels would only extract the round if a suppressor was mounted. It was that video that I finally got CMMG to replace my original barrel as proof that there was something unique going on with that barrel.

- I run about 99.9% suppressed and as mentioned above, it extracts just fine with a suppressor mounted even with no extractor installed in the bolt. I of course do use an extractor since you still need it to clear a live round. However, IME, it doesn’t have to work hard. I know many recommend getting the BCM extractor kit but I never found it helping the ejection failure issues myself.

- IME, best cased scenario is that you get around 1K before the MK10 ejector spring fails. Which BTW, if you read the entire article, you will see I have tested a bunch of different ejector springs, including the Bexar Inconel spring and nothing is as strong as the CMMG MK10 spring. Don’t waste your time measuring the MK10 spring length as it is shorter but has thicker gauge wire coils. It is best that you measure the strength of the ejector spring and get a feel for when it is time to replace. It is also faster since you are not taking the spring out of the bolt to do this. If you are at 5lbs or less, it will start to fail you. A new MK10 spring is around 10lbs to compress.

- Have a spare bolt with new spring ready to go.

- All the above is my advice if you want to stick with the system. Many will say this is too much of a PITA. However when you consider that the bolt / BCG combo is under $400 to get a delayed action that can be very smooth (especially if you use my A5 / RB5007 and flat spring combo) I think it is still worth it. Especially if you are looking for this in the AR15 / M16 platform and maintain the same manual of arms. Bonus points for SBR, RLL, RR, RDIAS owners.

- All that said, I dumped my 9mm CMMG RDB ‘Guard/Banshee’ for my hybrid CMMG RDB Dissent which uses a fixed ejector and tune-able as documented here: https://c3junkie.com/?page_id=1733.

I will also say that I have never impressed with the recoil impulse of a STOCK CMMG ‘Guard/Banshee’ OR the new 9mm CMMG Dissent. However if tuned they both can be amazingly smooth.

I still have my .40SW CMMG RDB ‘Guard/Banshee’ and just deal with swapping ejector springs at around the 800 round mark with that caliber. I also have it in .45ACP which I don’t shoot as much and haven’t seen ejector spring failure posts in .45 which also operates at a lower pressure.

Regarding tuning, unless you do custom machine work like I did for the Dissent, it cannot be tuned. The 9mm Dissent does have some bolt bounce that you can’t easily do anything about without custom work. The .45ACP ‘Guard/Banshee’ could handle .45 Super but the new Dissent cannot since it cannot be tuned.

The CMMG RDB system was initially introduced in .45ACP and they came out with a proprietary ejector spring for it. It is shorter than a standard 556 ejector spring and there have been people thinking it was weaker but it is thicker and actually stronger than a typical 556 ejector spring when new.

I was never interested in the .45ACP CMMG so waited till the 9mm version came out. However, I do have friends with the .45ACP RDB’s and none of them have had ejector spring failures but I don’t think any of them have run them as much as 9mm. Nor have I seen posts online about the 45 wearing out ejection springs. So I don’t know if .45ACP have the same problem.

When the 9mm came out they used standard 556 ejector springs and some people started reported ejection failures. CMMG then started to supply the 9mm RDB bolts with the same spring they were using in the 45ACP RDB.

In 9mm I was seeing failures around 1000 rounds. I also have the CMMG RDB in .40SW and the ejector spring failed around 900 rounds in that caliber as well. CMMG then released the MK10 (10mm RDB) in late 2019. They switched to a new material for the ejector spring that is being used in the MK10 and have been offering this new spring for those encountering ejector spring failures in their 9mm’s, .40SW and I guess .45ACP’s (although as I mentioned previously I haven’t heard of it happening).

In the picture below you can see that I also tried an HK416 spring and although it is a lot longer it isn’t that stiff and ended up not lasting long either.

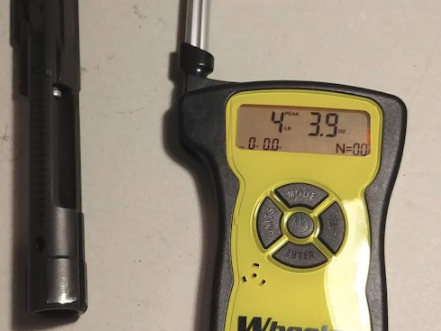

Picture below shows how strong a new “45ACP” Guard spring is in a 9mm RDB bolt.

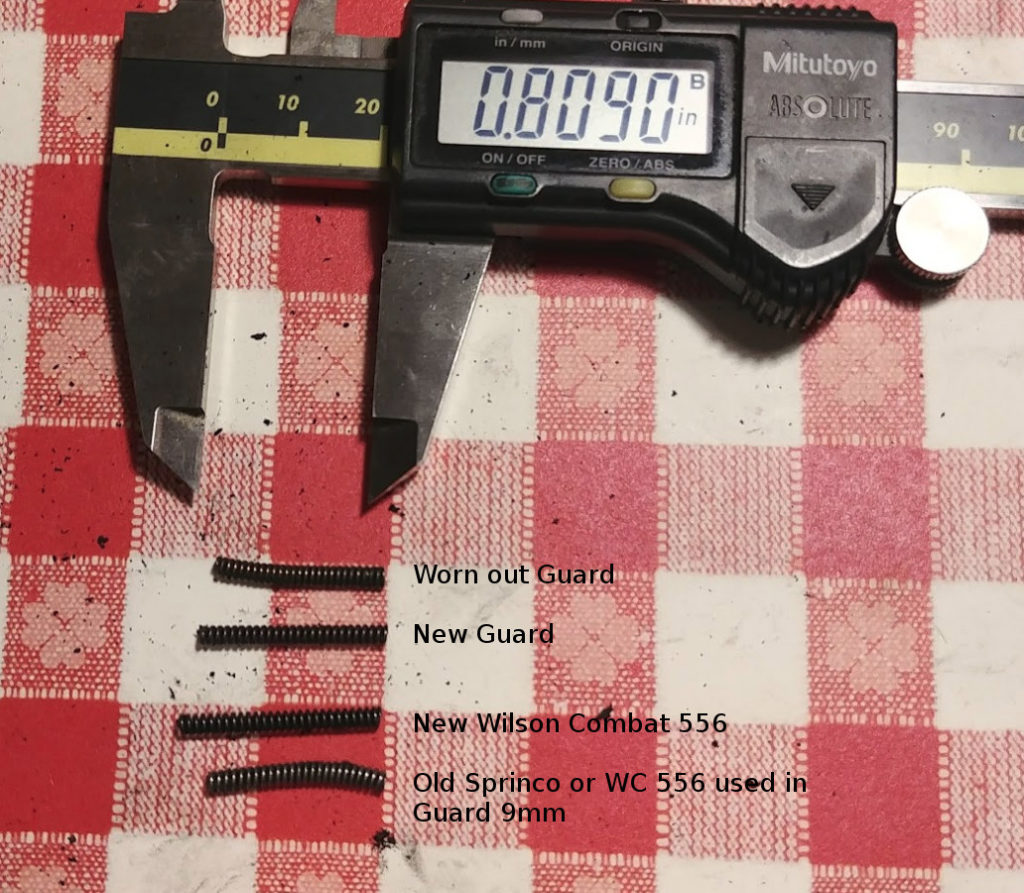

Picture below shows a new Wilson Combat 556 spring. This is barely enough to be reliable. Note that I see about the same amount of force for other ejector springs, Sprinco, Tubb, Sig and no-name brands, etc…only the CMMG RDB springs are significantly stronger than other 556 ejector springs.

In my testing when it gets around 5lbs or less, you are going to start having ejection failures.

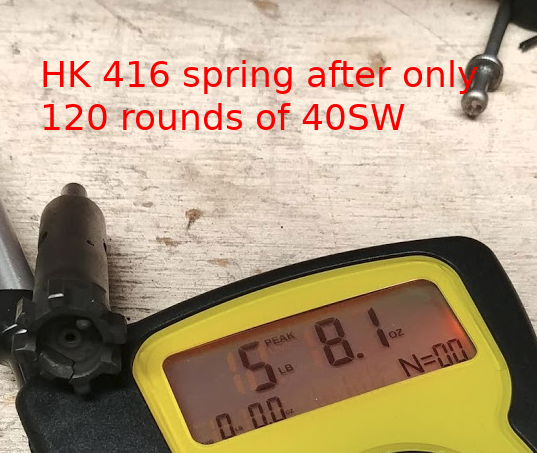

Brand new HK 416 bolt only has a little over 6lbs of force.

After only 120 rounds, you can see how much shorter the HK416 spring is.

Spring strength is close to 5 lbs (failure point).

Pictured below is a DPMS GII ejector, notice how the ejector pin has a built in guide to help prevent spring deformation.

I tried to replicate this by using a cut nail

I did some limited testing with this but no clear indication of increasing longevity as I stopped when I saw that CMMG mentioned that the new (as of late 2019) MK10 spring should resolve these issues. The picture below is using a CMMG .45 ejector spring not the MK10 spring.

MK10 spring length and strength when new.

I am running the MK10 spring in my .40SW RDB setup and at about 700 rounds so far with no issues but still haven’t gone past 1000 rounds yet to confirm if it lasts longer than the previous 45 RDB ejector spring.***5/3/20 UPDATE*** Ran close to 600 rounds today at a SMG match. On the first two stages, it was flawless. Next stage I had 3 FTE’s. I thought it may have had something to do with some new reloads and so went back to the same loads I ran in the first two stages and then I had at least 6 or 7 FTE’s. I’m done with the spring loaded ejector at this point.

So you may be wondering why we don’t have this problem in other AR15/M16 calibers using the ejector in the bolt like 5.56, 7.62×39 etc…The bolt is really locked into the extension and requires the pressure to build up in the carrier to push the carrier away from the bolt while the CMMG RDB doesn’t rely on the gas.

Also, there have been several posts where some people are beyond 3 or 4K of rounds even full auto suppressed on their original ejector springs and have no ejection issues at all.

I personally believe that the root cause of the ejection spring failures is there is too much slop in the headspacing of the barrel.

This video illustrates this slop:

I think that the people that are getting over 3 – 4K or higher on the original ejector spring in 9mm don’t have as much slop as seen in my video. I have (2) 9mm CMMG RDB BBL/BCG combos and (1) in .40SW and all 3 of them do this. Likewise, I’ve had ejector spring failures around the 1K mark in all 3 builds.

Some things to note, I think the slower the gun is cycling the more likely you are going to have ejection problems with this system and spring loaded ejector. As you can see in my tuning page, I’m trying to get the gun to run as slow and smooth as possible. I think this is why CMMG recommends going with a standard power buffer spring and standard carbine buffer. Both of which are going to have a much faster cyclic rate but also won’t be as soft / smooth as what I recommend.

I have asked CMMG if this headspacing slop is by design and was never given an answer. However, I did find that in my original 9mm build I was breaking a good bit of parts, it broke several extractor pins, firing pins and even broke their cam pin which BTW takes a lot of stress in this design and according to CMMG is made stronger than a typical 556 cam pin. When the cam pin broke, I took a closer look at what was going on. It turns out that the first 9mm CMMG RDB BBL/BCG combo that I bought which is the one that I was running the most and breaking parts could extract rounds with no extractor installed in the bolt. My 2nd CMMG 9mm barrel and .40SW barrel would not do this. However, if I added a suppressor all the barrels would extract with no extractor installed. I also had a custom stainless steel 9mm blowback barrel headspaced for a .40SW bolt with all the headspacing slop removed and it behaves like my 2nd CMMG 9mm barrel and .40SW barrel where it can only extract a round with no extractor installed if no suppressor is mounted. The following video illustrates this.

I had sent this video to CMMG and it took a lot of convincing but they finally swapped my original barrel for another one.

What I do know is that the custom SS barrel that I had made and headspaced to a .40SW bolt (since I was planning on using it for a dedicated suppressed barrel) while feels smooth, it is not reliable with any buffer/spring combo I tried with the spring loaded ejector as I think it is robbing too much energy away and there is not enough BCG velocity to reliably kick the brass out. I am dedicating that barrel to my fixed ejector setup which works great and has none of these issues.

I also even tried the new MK10 spring with my custom barrel that has no slop and it isn’t reliable either….so I think some slop is required for the spring loaded ejector….no slop then you need to fabricate a fixed ejector….

Wanted to post an update that I also got a MEAN Arms bearing delay upper which relies on the same ejector spring as the CMMG Banshee. I was bummed that they didn’t use a fixed ejector but gave it a chance. I had sporadic FTE’s with this upper as well. In less than 1000 rounds I pulled it apart and the ejector spring was broken. I replaced it with the stronger CMMG MK10 spring which died in under 300 rounds. Another subgunner also reached out to me with the same fate with his MEAN upper as well. He cannot make it through a 200 round match without FTE’s.

Some discussions have asked why this doesn’t happen in 5.56…that is because in 5.56 the bolt is truly locked. While in a delayed blowback, I do not think it is a good idea to have an ejector spring that is inline with the recoil impulse or it will be killed just like I have seen with both of these platforms.

I think a fixed ejector is the way to go which is why I went through all the trouble to build this: Ultimate Full Auto CMMG RDB Fixed Ejector Project (hybrid Dissent 9mm)